What is the IDOD and what does it do?

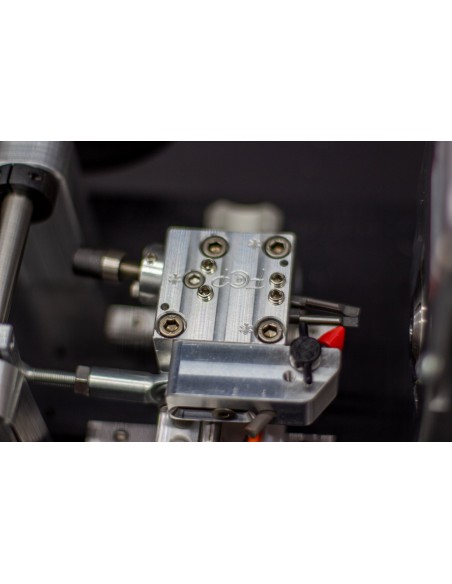

The IDOD name stands for "ID and OD," meaning it cuts both the Inner Diameter (ID) and Outer Diameter (OD) of the case neck in one operation. This process eliminates the formation of the "donut" that typically occurs with conventional mandrel-based turning systems. By doing this, it ensures minimal variations in case neck thickness. Additionally, the IDOD eliminates the need for lubrication, as there is no friction with the mandrel like in traditional systems. With the IDOD, the cutting process is uniform and does not require lubricants, simplifying cleanup and enhancing precision.

Includes:

- Plug adaptor (Italy)

- Regular size collet bushing

- New .308 WIN case holder

- 20° shoulder angle cutter

Case Holder Fitment and Full Inside/Outside Neck Clean-Up

We recommend turning brass in either its new or fired state, without any additional brass prep. In these states, the neck-to-body runout is at its minimal. When brass undergoes die expansion or other forms of brass prep, the neck can unintentionally misalign with the body.

You can turn your brass in any condition, but the most important factor is ensuring the brass neck is concentric with the body. This can be verified using a concentricity gauge.

The case is held in place by the case holder based on its taper. A case holder for new brass is made according to the manufacturer's taper, which can slightly vary between brands, requiring separate case holders for different brands. Fired brass alters the original taper and conforms to your chamber, necessitating custom-made case holders, which require sending your fired brass for proper fitment.

Your neck-to-body runout, when checked on a concentricity gauge, must be less than the amount you intend to cut. For example, if the runout is 0.004" and you are only cutting 0.002", you won't achieve 100% neck cleanup.

If the runout is 0.002", you need to cut at least 0.002" to get a complete cleanup. For instance, the 6.5x.284 Lapua brass, expanded to 7mm and full-length sized with a bushing-less die, has a neck wall thickness of approximately 0.014"-0.0145" before turning. When reduced to 0.0125" or thinner, sufficient cleanup is always achieved.

-

Prodtto correlati custom